|

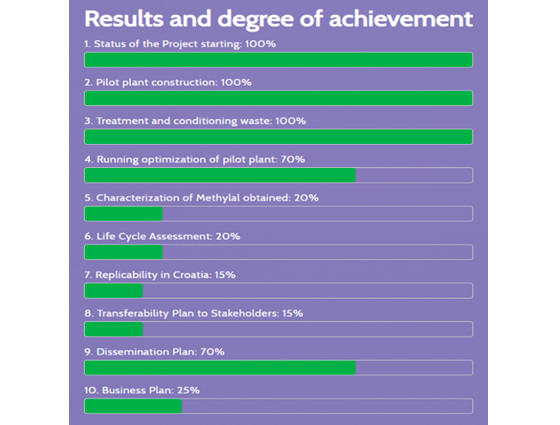

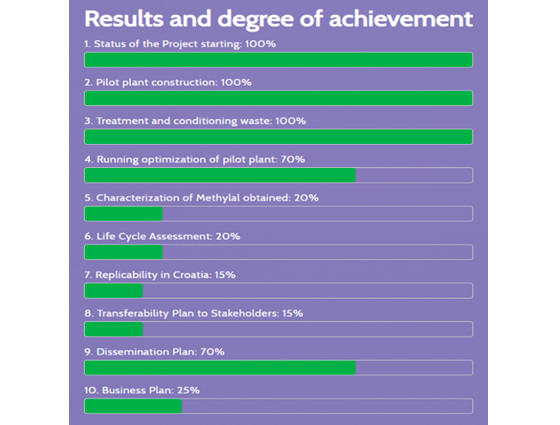

LIFE ECOMETHYLAL is a project running initially from 01/09/2016 to 31/03/2021. The work plan is divided into several actions. See below the summary of the main results and degree of achievement:

RESULT 1- Status of the Project starting. As a preparatory action, an overall assessment was made, by reviewing some aspects that could have changed since this proposal was submitted to the start of project implementation, mainly related to standards and/or legislation, current thermal recovery processes for mixed plastic waste fractions and their impact in the society, specific needed permits for the construction of the plant, planning the supply of materials needed for construction of the plant.

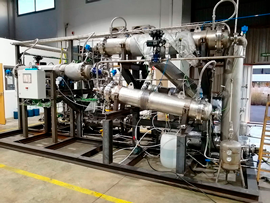

RESULT 2- Pilot plant construction. This implementation action has been the core of the project work since the very beginning of the project, and the one which have consumed most of the resources and expenses. This action includes an adaptation of the BPP process to the conditions and foreseen waste for the LIFE-ECOMETHYLAL project, design and building drawings of the gasification and liquid ECOMETHYLAL synthesis unit, resulting in the successful pilot plant construction by the end 2019. See pictures further below.

RESULT 3- Treatment and conditioning waste. Partners worked on the definition of the waste modifications and pre-treatment stages required, in order to achieve an adequate composition and physical characteristics for their effective transformation (methylal) in the subsequent action, involving the pilot plant optimization. Plastic waste provided by the partners was distributed in five different flows and the corresponding characterizations and technical datasheets were done. The best combinations and suitable characteristics for the potential future plastic waste streams were identified.

RESULT 4- Running optimization of the pilot plant. Since last October 2019, the project pilot plant started to run completely, with the aim of optimizing their performance as much as possible before the industrial trials in ACTECO´s industrial facilities (foreseen by next end August 2020). A series of improvements related to the pilot plant security, efficiency and quality of the final ecomethylal were applied. The ultimate goal is to transfer the pilot plant to the industrial environment (in ACTECO´s facilities), ensuring that all the different technical, assembling & logistic parameters are under control.

RESULT 5- Characterization of the methylal obtained. First of all, the setting if the characterization protocol was necessary to be defined and well-established (based on commercial samples), as this was a new product coming from waste. Then, with the different runs in the pilot plant and the optimization trials, ecometylal samples were characterized. Further trials are expected along its optimization before / during and after the 2 industrial workshops (1st- In ACTECO´s facilities, in Spain; and 2nd in MIPLAST´s facilities, in Croatia).

RESULT 6- Life Cycle Assessment. The monitoring of the environmental aspects (apart from the economic and social ones), is one of the key project points. This is an ongoing task until the project end, that is now still in progress, gathering the necessary information at pilot plant level (at BPP´s facilities). Subsequent stages are needed (collecting data from ACTECO´s & MIPLAST´s trials), and making comparisons, and final analysis.

RESULT 7- Replicability in Croatia. Partners have been focused on arranging ACTECO´s workshop (in Ibi, Alicante), but also part of their advancements have been useful to define the first steps in Croatia- MIPLAST, dealing with aspects such as the venue, conditions of the facilities, people & profiles to be invited, approximated workshop costs, workforce needed on behalf of BBP & MIPLAST, transfer conditions of the pilot plant and connections/assembly scenario, etc.

RESULT 8- Transferability Plan to Stakeholders. The LIFE ECOMETHYLAL consortium has been working since the very beginning to spread the project objectives & progress of the results to as many stakeholders as possible, making relevant contacts with potential external stakeholders (both at public & private level). In section PROJECT ACTIVITIES- STAKEHOLDERS of website, you will find the non-confidential list of them, gathered so far (and those who are officially invited to take part in ACTECO´s workshop, face-to -face by streaming). It is expected to increase these interactions after ACTECO´s workshop (with the B2B´s meetings offered), and, in MIPLAST´s workshop, partners will perform similarly.

RESULT 9- Dissemination Plan. Partners have been active in all the Communication & Dissemination (C&D) activities and Public awareness. In PROJECT ACTIVITIES- ACTIVITIES of website, you will find an example of the set of actions carried out to promote mainly the project objectives. A wide range of usual C& D activities have been implemented, from technical articles, attendance in trade fairs, through workshops and conferences, to press releases and infodays; at regional, national & EU level. From now on, through this newsletter, the 2 workshops plus the questionnaire´s analysis, more feedback on the pilot plant performance, project results and sustainability will be published.

RESULT 10- Business Plan. LIFE ECOMETHYLAL seeks for a viable business model for partners involved and the future potential stakeholders. The consortium is convinced that it will contribute to implement and spread the project´s environmental benefits, new technology and LIFE-ECOMETHYLAL plastic waste management solution, all around EU. The preliminary basis for a future Business Plan and Commercial Strategy among the consortium members have already been defined, but in the coming months, much more details in terms of investment, market penetration, future plants to be installed through identified stakeholders, products´ prices, and potential sectors, as well as the plastic waste logistic will be studied and analysed.

RESULT 10- Business Plan. LIFE ECOMETHYLAL seeks for a viable business model for partners involved and the future potential stakeholders. The consortium is convinced that it will contribute to implement and spread the project´s environmental benefits, new technology and LIFE-ECOMETHYLAL plastic waste management solution, all around EU. The preliminary basis for a future Business Plan and Commercial Strategy among the consortium members have already been defined, but in the coming months, much more details in terms of investment, market penetration, future plants to be installed through identified stakeholders, products´ prices, and potential sectors, as well as the plastic waste logistic will be studied and analysed.

|